3D Printing SErvices

What is 3D Printing?

3D printing, also known as additive manufacturing, is a revolutionary process that uses digital models to create three-dimensional objects. Unlike traditional manufacturing methods that require cutting or hollowing out pieces from a solid block of material, 3D printing uses materials such as plastics, metals and resins to build objects layer by layer. The technique begins by designing a 3D model using computer-aided design (CAD) software, which is then cut into thin cross-sections. The 3D printer reads these slices and deposits material precisely based on the digital blueprint.

3D printing is versatile and used in a variety of industries, including aerospace, automotive, healthcare, and consumer products. It supports rapid prototyping, allowing designers and engineers to quickly test and iterate their designs. Additionally, 3D printing can be used to produce complex custom parts that would be difficult or impossible to create using traditional manufacturing techniques. The technology not only speeds up the design process, it also reduces waste and enables greater innovation in product development.

Advantages of 3D Printing

- Design flexibility

3D printing can create complex designs that are difficult or impossible with traditional manufacturing methods. Designers can generate geometric shapes with internal structures, overhangs and detailed features without the need for specialized tools. - Rapid prototyping

One of the most significant advantages of 3D printing is the ability to rapidly produce prototypes. This rapid prototyping enables designers and engineers to test and refine their designs faster, shortening development cycles and accelerating time to market. - Small batch production is cost-effective

Traditional manufacturing methods, such as injection molding, require expensive molds and tooling. 3D printing eliminates the need for these, making it a cost-effective solution for producing small batches or one-off custom products. - Customization and personalization

3D printing excels at producing products customized to individual needs. This is particularly beneficial for industries such as healthcare, where custom prosthetics, dental implants and hearing aids can be created based on each patient’s unique anatomy. - Reduce waste

Essentially, additive manufacturing uses only the material needed to make the part, significantly reducing waste compared to subtractive manufacturing methods like milling or turning that cut away excess material.

- On-Demand Manufacturing

3D printing allows for on-demand production, reducing the need for large inventories. Parts can be printed as needed, which minimizes storage costs and reduces the risk of overproduction. - Supply Chain Simplification

With 3D printing, parts can be produced closer to their point of use, reducing the need for complex supply chains and long lead times. This is particularly useful for remote locations or in scenarios requiring rapid deployment of parts. - Material Variety

3D printing supports a wide range of materials, including various plastics, metals, ceramics, and even composites. This versatility allows for the creation of parts with specific properties tailored to their application. - Innovation and Creativity

The freedom to design without traditional manufacturing constraints encourages innovation. Designers and engineers can experiment with new ideas and approaches, leading to more innovative products and solutions. - Environmental Impact

By reducing waste and enabling local production, 3D printing can have a positive environmental impact. It also allows for the use of sustainable and recyclable materials, further contributing to eco-friendly manufacturing practices.

Common 3D Printing Technologies

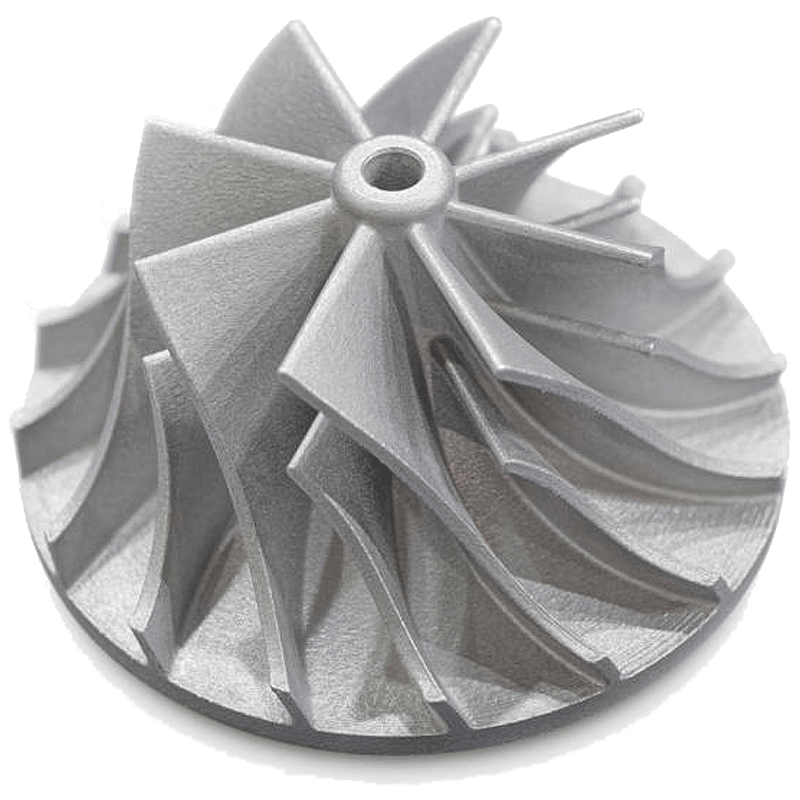

1. Fused Deposition Modeling (FDM)

Builds objects layer by layer by heating and extruding thermoplastic material. Materials: PLA, ABS, PETG, TPU, etc. Applications: Prototyping, hobbyist projects, functional parts.

2. Stereolithography (SLA)

Uses a laser to cure liquid resin into hardened plastic, layer by layer. Materials: Photopolymer resins. Applications: High-precision parts, dental models, jewelry, prototypes.

3. Selective Laser Sintering (SLS)

Uses a laser to sinter powdered material, fusing particles together, layer by layer. Materials: Nylon, polyamides, and other polymers. Applications: Functional prototypes, small-batch production, complex geometries.

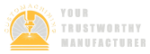

4. Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM)

Uses a laser to sinter or melt metal powders, layer by layer, to create metal parts. Materials: Stainless steel, aluminum, titanium, and other metal alloys. Applications: Aerospace, automotive, medical implants, high-performance industrial parts.

5. Digital Light Processing (DLP)

Uses a digital projector screen to flash an image of each layer across a vat of liquid resin, curing it layer by layer. Materials: Photopolymer resins. Applications: High-detail prototypes, dental applications, jewelry.

Advantages of 3D Printing

1. Design the Model

Create a 3D model using CAD software or download one from an online repository.

2. Convert to STL Format

Convert the 3D model into an STL file that approximates the shape using triangles.

3. Slice the Model

Use slicing software to divide the STL file into thin horizontal layers and generate G-code instructions.

4. Setup the 3D Printer

Load the printer with the appropriate material and calibrate the print bed.

5. Printing Process

The printer deposits material layer by layer according to the G-code instructions, using the chosen 3D printing technology.

6. Post-Processing

Remove support structures, clean the printed object, and apply any necessary finishing touches.

7. Final Product

Inspect the final product for quality and accuracy before it is ready for use.

Turn Concepts Into Reality

All information and uploads are secure and confidential.

Why Choose Customachining 3D Printing?

Request a Quote

If you already have the drawings, please send email to [email protected] directly for an instant quote.

Work with Customachining

Get a CNC Machining Solution with Easy

Let’s Start Our Cooperation with the 3 steps to start now!

1. Tell Us What You Need

Send us your request with details and share your idea.

2. Get Solution and Quote

We will work on the best solution base on your request and send you a specific quote within 24 hours.

3. Support at All Times

Whether it is before or after the sale, we are always here to support you.