CUSTOMACHINING

CUSTOMACHINING

The Standard Components We Did

Straight Radius Rod

Recommended Material: 6061 or 7075 Aluminum Alloy (selected based on strength requirements)

Application: Suitable for suspension systems in general off-road and road vehicles.

Benefits: 6061 aluminum alloy offers lightweight, corrosion resistance, and sufficient strength for standard usage; for high-load requirements, 7075 aluminum provides enhanced impact resistance and durability.

Advantages: 6061 offers excellent cost-effectiveness and durability, while 7075 provides higher strength, making it ideal for intense off-road or competitive environments.

High Clearance Radius Rod

Recommended Material: 7075 Aluminum Alloy

Application: Designed for extreme off-road conditions, suitable for complex terrains requiring high ground clearance, such as rocky landscapes and deserts.ion systems in general off-road and road vehicles.

Benefits: 7075 aluminum alloy has strength comparable to mild steel, ensuring it will not deform or break under high-stress conditions, ideal for enduring extreme off-road impacts.

Advantages: Lighter than traditional materials while offering excellent torsional strength and durability, making it perfect for high-clearance components with superior structural integrity.

Radius Rod Plate

Recommended Material: 6061 or 7075 Aluminum Alloy

Application: Used as a support and connection plate in suspension systems, suitable for high-strength support applications.

Benefits: 6061 offers sufficient strength and corrosion resistance, suitable for most standard applications; 7075 excels in high-load environments, making it perfect for demanding suspension systems.

Advantages: High-strength aluminum construction ensures vehicle stability and shock resistance in rough terrains, while keeping the overall weight lighter.

Rod End

Recommended Material: 6061 or 7075 Aluminum Alloy

Application: Widely used for ball-joint connections in suspension and steering systems, suitable for road vehicles, off-road vehicles, and racing cars.

Benefits: 6061 provides a durable and lightweight solution for standard applications; 7075 is ideal for high-stress environments, ensuring stability in high-speed or aggressive maneuvers.

Advantages: 6061 offers excellent cost-effectiveness, while 7075 provides additional strength, ensuring operational stability and long-lasting performance.

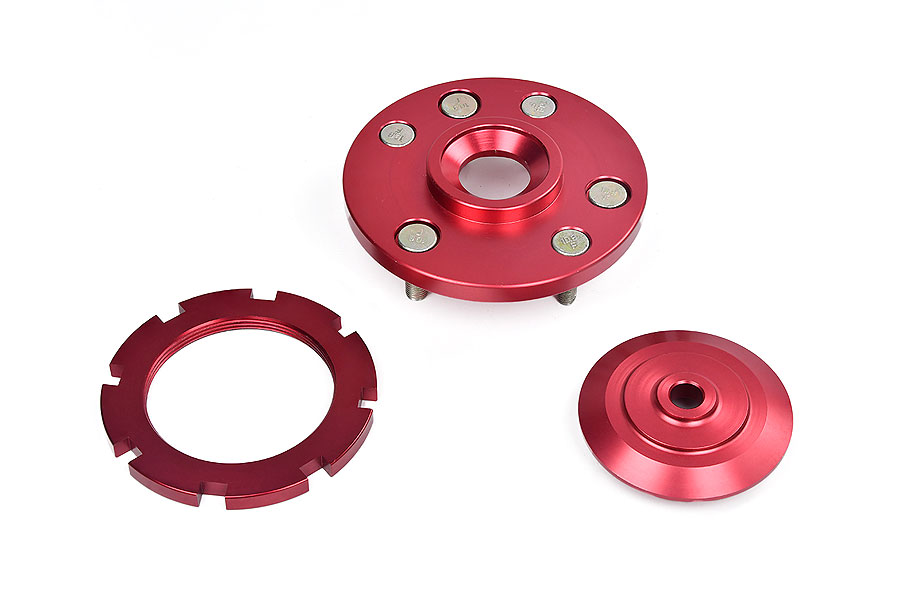

Wheel Spacer

Recommended Material: 6061 or 7075 Aluminum Alloy

Application: Used for track width extension in modified vehicles, off-road cars, and high-performance vehicles, enhancing vehicle stability.

Benefits: 6061 is ideal for most modification needs, being lightweight and easy to install; for higher strength demands, 7075 can be chosen to handle higher loads and prolonged use.

Advantages: 6061 offers excellent corrosion resistance and lightweight construction, while 7075 provides superior strength for intense handling and complex terrains.

Coil-over Sleeve

Recommended Material: 6061 Aluminum Alloy

Application: Precision adjustment component in shock absorber systems, compatible with various racing and off-road vehicle shock needs.

Benefits: 6061 provides high corrosion resistance and excellent machinability, ensuring stability and durability in shock adjustment components.

Advantages: High-precision manufacturing accommodates various shock systems, offering precise tuning capabilities to enhance vehicle suspension performance and handling.

Control Arm

Recommended Material: 6061 or 7075 Aluminum Alloy

Application: A crucial component in suspension systems, suitable for off-road vehicles, racing cars, and modified vehicles for suspension upgrades.

Benefits: 6061 is lightweight and strong, ideal for standard needs; 7075 provides enhanced durability and load-bearing capacity in high-strength applications.

Advantages: Provides stable support to ensure the suspension system maintains balance at high speeds or on complex terrains.

Sway Bar Link

Recommended Material: 6061 Aluminum Alloy

Application: A connection component in anti-roll bar systems, suitable for off-road vehicles, racing cars, and everyday vehicles.

Benefits: 6061 aluminum is lightweight and corrosion-resistant, ensuring the anti-roll bar performs well in aggressive driving or uneven surfaces.

Advantages: 6061 material ensures stability while reducing weight, making it ideal for a variety of complex terrains, enhancing vehicle handling and safety.

Custom Parts

Recommended Material: 6061 or 7075 Aluminum Alloy

Application: Customer Specific Situation

Benefits: 6061 is lightweight and strong, ideal for standard needs; 7075 provides enhanced durability and load-bearing capacity in high-strength applications.

Advantages: Provides stable support to ensure the suspension system maintains balance at high speeds or on complex terrains.

CUSTOMACHINING

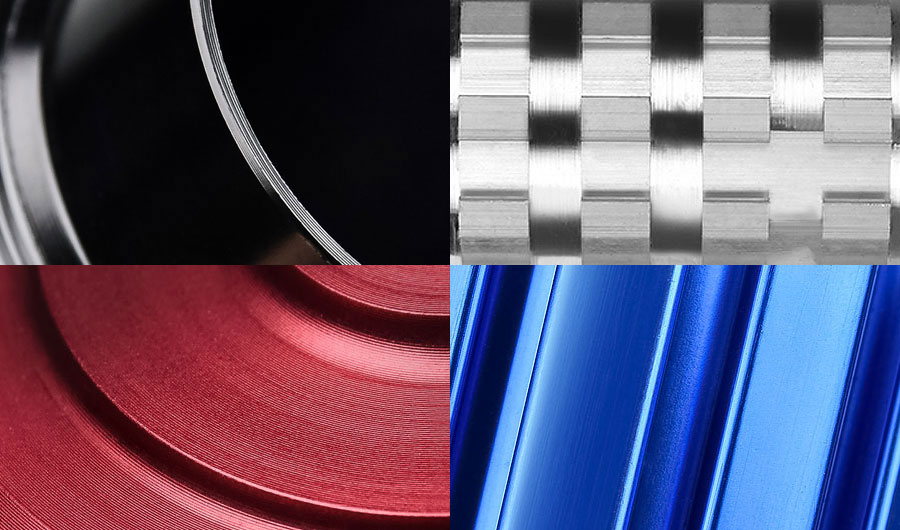

Common Aluminum Finishes

Anodizing: Creates a durable oxide layer on the aluminum surface, improving corrosion resistance and wear durability. Available in a range of colors, it also enhances the product’s aesthetic appeal. Ideal for components exposed to harsh environments or requiring a premium finish.

Electroplating: Adds a metallic coating to the surface, enhancing conductivity, corrosion resistance, and hardness. Perfect for components needing a glossy or decorative finish.

Powder Coating: Provides a durable, uniform, and vibrant finish that resists chipping, scratching, and fading. Suitable for parts requiring robust protection and customization in appearance.

Sandblasting: Produces a matte, textured surface finish by blasting fine abrasive particles, improving grip and preparing the surface for additional coatings. Ideal for mechanical parts or parts requiring minimal reflectivity.

Brushing: Creates a satin or brushed texture that enhances visual appeal while hiding minor surface imperfections. Commonly used for decorative and consumer-facing components.

CUSTOMACHINING

Characteristics and Advantages of Aluminum Parts

Material Characteristics:

- Lightweight: Aluminum’s density is only about one-third that of steel, making it an excellent choice for reducing overall vehicle weight and improving fuel efficiency.

- Superior Thermal Conductivity: Aluminum dissipates heat efficiently, making it ideal for components like control arms and suspension parts where heat management is critical.

- High Strength-to-Weight Ratio: Particularly true for alloys like 7075, which provides near-steel strength while maintaining the lightweight advantage.

CNC Machining Advantages:

- Durability: Combined with the right aluminum alloy, CNC-machined parts withstand high stress, impact, and environmental factors, offering longevity and reliable performance.

- Precision and Consistency: Advanced CNC machining ensures tight tolerances and repeatability, critical for applications like suspension systems and steering components.

- Customizability: CNC machining allows for intricate designs and complex geometries tailored to specific vehicle needs, making it suitable for high-performance or specialized vehicles.

- Enhanced Surface Quality: The machining process produces smooth, defect-free surfaces that can be directly treated or coated, enhancing both aesthetics and durability.

About Our Projects Flow

Let’s Work on Your Prototypes and Custom Parts with The 4 Simple Steps

Why Choose Customachining?

Turn Concepts Into Reality

All information and uploads are secure and confidential.

CUSTOMACHINING

Latest Blogs

Request a Quote

If you already have the drawings, please send email to [email protected] directly for an instant quote.

Work with Customachining

Get a CNC Machining Solution with Easy

Let’s Start Our Cooperation with the 3 steps to start now!

1. Tell Us What You Need

Send us your request with details and share your idea.

2. Get Solution and Quote

We will work on the best solution base on your request and send you a specific quote within 24 hours.

3. Support at All Times

Whether it is before or after the sale, we are always here to support you.