CNC Milling Services

CUSTOMACHINING

Precision CNC Turning Services

Our CNC turning services provide high-precision, cost-effective solutions for creating your parts. Utilizing state-of-the-art CNC lathes and a skilled team of machinists, we ensure efficient production for both small and large batches. Whether for automotive, aerospace, or industrial applications, our turning services guarantee top-quality, reliable components that meet the most stringent specifications.

Max. Parts Sizes

Max. Dia.:

508 mm / 20 in

Max. Length:

1066.8 mm / 40 in

Max Swing Over Tool Post:

355.6 mm / 14 in

Max. Through-Spindle Dia.:

50.8 mm / 2 in

CNC Milling Tolerance

Linear Dimension: +/- 0.025 mm, +/- 0.001 inch

Hole Diameters (not reamed): +/- 0.025 mm, +/- 0.001 inch

Shaft Diameters: +/- 0.025 mm, +/- 0.001 inch

Part Size Limit: 1200 * 800 * 600 mm, 47.0 * 31.4 * 23.5 inch

CUSTOMACHINING

Custom CNC Turning Parts

CUSTOMACHINING

CNC Materials For CNC Turning Services

Check The Characteristics of Materials to Choose the Best One for Your Project, Click “View All” to Learn More.

| Aluminum | 2024, 5052, 5083, 6063, 6061, 6082, 7050, 7075 |

| Stainless Steel | 17-4, 18-8, 303, 304, 316, 416, 420, 430, 410, 440C, 321, 347 |

| Brass | C36000, C26000, C28000, C37700, C48500, C22000, C23000, C24000 |

| Copper | C11000, C10100, C14500, C17200, C18200, C19400, C10200, C12200 |

| Titanium | Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, Grade 7, Grade 9 |

| Steel | A36, 1018, 1020, 1045, 4140, 4340, 8620, 9310 |

| Plastic | POM, ABS, Nylon, PEEK, PTFE, PAI, PMMA, PEI, HDPE, PVC, PPS, PC, UHMW |

CUSTOMACHINING

CNC Surface Finishes For CNC Turning Services

Check The Characteristics of Materials to Choose the Best One for Your Project, Click “View All” to Learn More.

| As Machined | Surface left as is post-machining, shows tool marks. |

| Smoothing | Reduces surface roughness, improves appearance and texture. |

| Painting | Applies a colored coating for aesthetics and protection. |

| Passivation | Enhances corrosion resistance by removing free iron from surfaces. |

| Powder Coating | Durable, powder-applied finish, baked to form a hard coat. |

| Anodizing II | Electrochemical process creating a shiny or dull, corrosion-resistant layer. |

| Anodizing III Hard Coat | Thick, wear-resistant anodized layer for high durability. |

| Polishing | Creates a smooth, shiny surface by mechanical abrasion or chemical treatment. |

| Black Oxide | Black conversion coating providing corrosion resistance. |

| Bead Blasting | Bead blasted with glass beads to clean and texture surfaces. |

| Sandblasting | Uses high-pressure sand to clean and texture surfaces, creating a matte finish. |

| Chrome Conversion Coating | Improve the corrosion resistance while maintaining conductive properties. |

| Plating | Corrosion resistance, with solderability and electrical conductivity, various material options, such as zinc, chrome, nickel, tin, etc.. |

CUSTOMACHINING

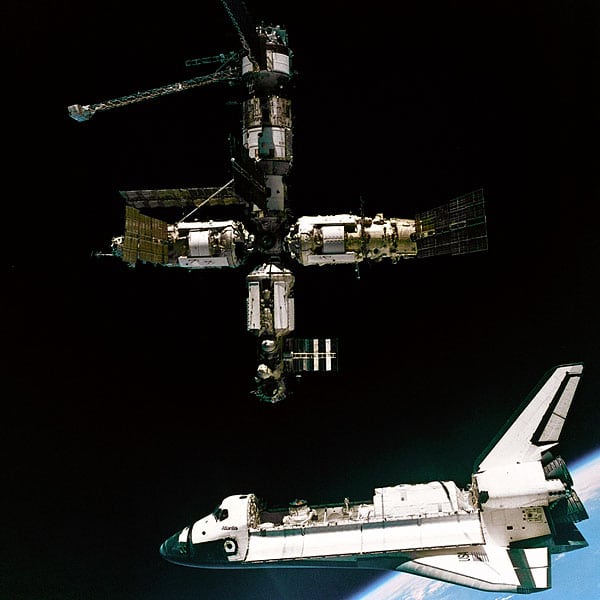

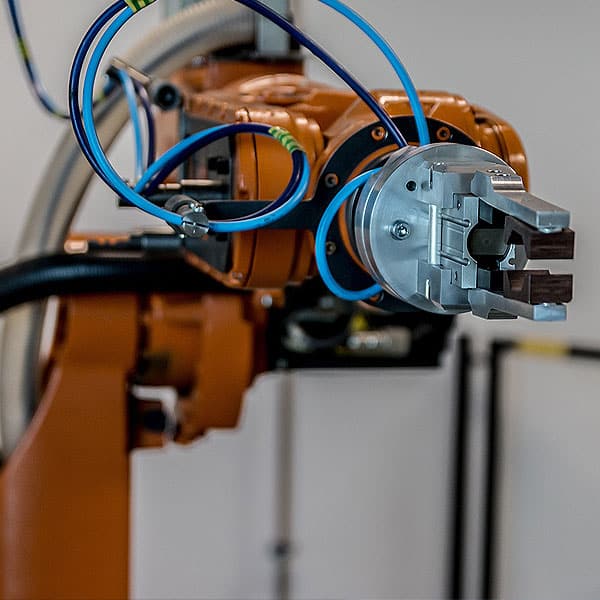

Highlighted Industries We Served

We Serve Aerospace, Automotive, Automation, Medical, Robotics,Energy, Consumer Products, Industrial, ect.

CUSTOMACHINING

Why Choose Us for CNC Machining Parts

Request a Quote

If you already have the drawings, please send email to [email protected] directly for an instant quote.

Work with Customachining

Get a CNC Machining Solution with Easy

Let’s Start Our Cooperation with the 3 steps to start now!

1. Tell Us What You Need

Send us your request with details and share your idea.

2. Get Solution and Quote

We will work on the best solution base on your request and send you a specific quote within 24 hours.

3. Support at All Times

Whether it is before or after the sale, we are always here to support you.