Injection molding Services

CUSTOMACHINING

Injection Molding Capabilities

We Are Always Here To Serve You, Email: [email protected]

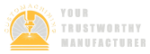

Injection Mold Tooling

Plastic Injection Molding

Metal Injection Molding

Turn Concepts Into Reality

All information and uploads are secure and confidential.

What Is Injection Molding?

Injection molding is a widely used manufacturing process that produces parts by injecting molten material into a mold. It has the advantages of high production efficiency, large material selectivity and high parts consistency. Injection molding can use a variety of materials, including metals, glass, etc., but most commonly various plastics. The main process flows are material preparation, melting, injection, cooling, demoulding, and post-processing.

Plastic Material of Injection Molding

Plastic materials are widely used in injection molding and can be mainly divided into thermoplastic plastics and thermosetting plastics. Thermoplastics can be heated and cooled multiple times to form plastics that soften when heated and harden when cooled. Thermoplastics mainly include HDPE, LDPE, PP, PVC, GPPS, HIPS, ABS, PA, PC, etc. Thermosetting plastics undergo a chemical reaction and solidify after being heated, and cannot be melted again after molding. Thermosetting plastics include EP, PF, UP, etc.

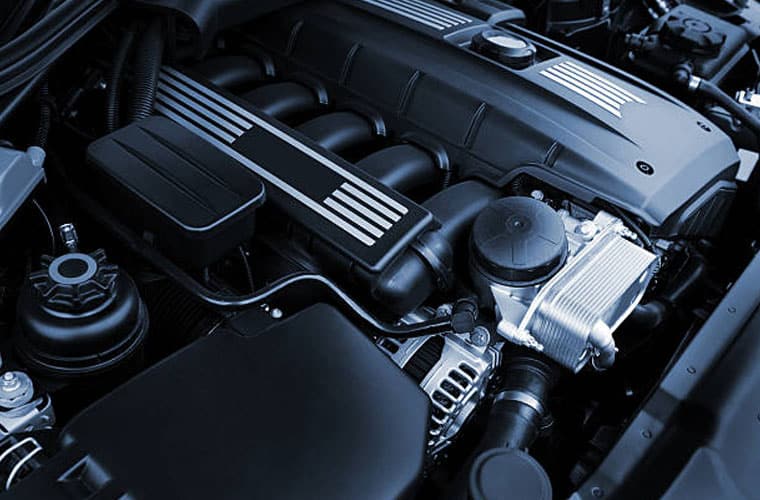

Metal Material of Injection Molding?

Metal Injection Molding (MIM) is a technology that mixes metal powder with a binder and then manufactures parts with complex shapes through the injection molding process. This technology combines the advantages of plastic injection molding and powder metallurgy to produce high-precision, high-performance metal parts. Commonly used materials include stainless steel, iron-based steel, copper alloy, titanium alloy, nickel-based alloy, etc. The main processes are mixing, injection molding, degreasing and sintering. The advantages of metal injection molding are that it can manufacture parts with complex geometries and high precision, reducing subsequent steps, high material utilization, and high production efficiency.

Various Surface Finishes Options

The choice of surface finishes should be considered based on comprehensive factors such as the product’s own materials, aesthetic and functional requirements, use environment, cost and production efficiency. Common Injection Molding Surface Finishes:

- Polishing: Improve surface finish and increase product aesthetics

- Spray: Add color and texture, provide a protective layer

- Electroplating: Improve corrosion resistance, increase metal texture and aesthetics

- Printing: Add logo, text, pattern and other information

- Laser engraving: Using laser to carve fine patterns or text on the surface, with high precision and durability

- Sand blasting: to form a matte or rough surface to improve the grip or decorative effect

- Anodizing: Enhance wear resistance and corrosion resistance, increase surface hardness and color

- Texture processing: By creating texture on the mold, a specific texture effect is formed on the surface of the injection molded part

CUSTOMACHINING

Other Injection Molding Service

Overmolding and Insert Molding Services are Also Available, Please Contact Us to Get an Instant Reply.

Overmolding

Combinations of different materials such as plastic and plastic, plastic and rubber. It is usually a two-step process, with the base material formed first and then overmolded. It is mostly used to improve the functionality and aesthetics of products, such as anti-slip, soft touch, etc.

Insert Molding

A combination of plastic with metal components or other prefabricated components. The insert is placed into the mold and then injection molded, saving production costs and time. Mainly used to enhance the structural strength and functions of products.

CUSTOMACHINING

Why Choose Us for Injection Molding Service

Request a Quote

If you already have the drawings, please send email to [email protected] directly for an instant quote.

Work with Customachining

Get a CNC Machining Solution with Easy

Let’s Start Our Cooperation with the 3 steps to start now!

1. Tell Us What You Need

Send us your request with details and share your idea.

2. Get Solution and Quote

We will work on the best solution base on your request and send you a specific quote within 24 hours.

3. Support at All Times

Whether it is before or after the sale, we are always here to support you.