CUSTOMACHINING

CUSTOMACHINING

Most Popular Design We Did

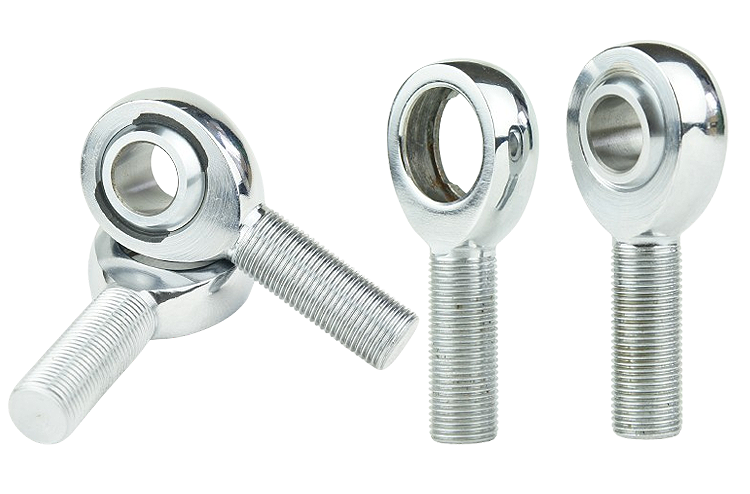

Aluminum Rod Ends

Aluminum rod ends are widely used in applications where both strength and lightweight properties are essential.

Automotive and Racing

Aluminum rod ends are used in suspension systems, linkages, steering components, and throttle bodies, particularly in performance vehicles where weight savings can improve speed and handling.

Aerospace

Due to their lightweight and corrosion-resistant nature, aluminum rod ends are ideal for aerospace applications, including control linkages, actuators, and landing gear systems.

Motorcycles and Bicycles

Used in high-performance motorcycle and bicycle suspensions, linkages, and custom builds, aluminum rod ends contribute to a lightweight, strong frame and improved maneuverability.

Industrial Machinery

In light-duty industrial machinery, aluminum rod ends are used in articulating joints, pivots, and linkages where reduced weight and corrosion resistance are essential for longevity and efficient operation.

Marine Equipment

Aluminum’s corrosion resistance makes it suitable for marine applications, such as boat rigging, control systems, and linkages, where exposure to water is a concern.

Lightweight and High Strength

Aluminum rod ends provide a strong, lightweight solution ideal for applications requiring efficient weight reduction without sacrificing performance or durability.

Corrosion Resistance

Aluminum is naturally corrosion-resistant, which means aluminum rod ends can withstand harsh environments, reducing the need for additional coatings or maintenance.

Heat Dissipation

Aluminum dissipates heat more effectively than many other materials, making it suitable for applications with high thermal loads, such as engines and other high-speed machinery.

Ease of Machining and Customization

Aluminum is easy to machine, allowing for precise manufacturing of custom designs, specialized threading, or unique shapes to meet specific application needs.

Cost-Effective

Compared to other high-performance metals, aluminum offers a more affordable option without sacrificing significant strength or durability, especially for applications not requiring extreme load-bearing capabilities.

Chromoly Rod Ends

Chromoly rod ends are designed for heavy-duty applications that require exceptional strength, durability, and resistance to stress and strain.

Off-Road and Racing Vehicles

Chromoly rod ends are ideal for off-road and racing applications, such as suspension systems, steering linkages, and control arms, where they handle the high stress and impacts of rough terrains and extreme driving conditions.

Automotive Suspension and Drivetrain Components

Due to their strength, chromoly rod ends are frequently used in the suspension systems of high-performance and heavy-duty vehicles, including control links and anti-sway bars in trucks and SUVs.

Industrial and Heavy Equipment

Chromoly rod ends are used in construction and agricultural machinery where they provide reliable performance in demanding settings. Applications include articulating joints, hydraulic systems, and pivots in cranes, loaders, and excavators.

Motorsports and Custom Builds

In motorsports, including drag racing, drift racing, and custom car builds, chromoly rod ends are essential for stability and strength in high-stress areas such as chassis connections, suspension joints, and stabilizers.

Aerospace Applications

Chromoly’s exceptional strength-to-weight ratio makes it suitable for critical aerospace applications like actuators, control surfaces, and landing gear where maximum durability is required.

High Strength and Durability

Chromoly (an alloy steel primarily composed of chromium and molybdenum) is known for its impressive strength, enabling chromoly rod ends to withstand high stresses and loads without deforming, even under continuous impact.

Enhanced Resistance to Fatigue and Wear

Chromoly rod ends provide excellent resistance to wear, fatigue, and metal fatigue, making them suitable for high-cycle applications and environments with substantial vibration and mechanical stress.

Superior Heat Resistance

Chromoly retains its strength at higher temperatures, making it an ideal choice for applications involving high-speed movement or intense friction, such as automotive suspensions and engines.

Long Service Life

Due to their resilience and wear resistance, chromoly rod ends generally offer a longer lifespan, reducing the need for frequent replacements and minimizing maintenance costs in heavy-duty applications.

High Precision and Stability

Chromoly can be machined to tight tolerances, providing a stable, precise connection point that is crucial for performance in areas like suspension and steering where consistent geometry is needed.

Stainless Steel Rod Ends

Stainless steel rod ends are highly versatile and are commonly used in various industries where corrosion resistance, strength, and durability are essential.

Automotive and Racing

Stainless steel rod ends are widely used in suspension systems, linkages, and steering components of high-performance and racing vehicles due to their strength and resistance to corrosion from road salts and other environmental factors.

Marine and Offshore

In marine environments, where exposure to saltwater and humidity is constant, stainless steel rod ends provide superior resistance to corrosion, making them ideal for boat rigging, control systems, and other marine applications.

Industrial Machinery

Stainless steel rod ends are used in various industrial machinery applications, such as actuators, pivot joints, and linkages in environments where both strength and corrosion resistance are required. They are commonly found in food processing, pharmaceutical, and chemical industries.

Agricultural Equipment

Stainless steel rod ends are used in agricultural machinery for controlling and stabilizing movements in systems like hydraulic actuators, linkages, and steering components, where they are exposed to harsh weather and chemicals.

Aerospace and Military

Stainless steel’s corrosion resistance and high strength make it suitable for aerospace and military applications, such as control systems, actuators, and other critical components that must perform in extreme conditions.

Corrosion Resistance

The primary advantage of stainless steel rod ends is their exceptional resistance to corrosion, even in harsh environments like saltwater, chemicals, and extreme weather conditions. This makes them ideal for use in marine, industrial, and food-processing applications.

Strength and Durability

Stainless steel rod ends combine high tensile strength with excellent durability. They can handle high loads and extreme conditions without cracking or deforming, making them ideal for demanding applications like racing and heavy machinery.

Long Service Life

Stainless steel rod ends are highly durable and resistant to wear, which results in a longer service life. Their corrosion resistance means that they do not need frequent maintenance or replacements, offering long-term performance.

Ease of Cleaning and Maintenance

Stainless steel is easy to clean, making it particularly useful in industries like food processing, pharmaceuticals, and marine, where hygiene and sanitation are essential. They are resistant to the buildup of rust and contaminants.

High Temperature Resistance

Stainless steel rod ends can withstand high temperatures without losing their strength or structural integrity. This makes them suitable for high-performance automotive applications, as well as industrial environments where heat exposure is common.

Precision and Customization

Stainless steel can be precisely machined, allowing for the production of custom sizes, shapes, and configurations to meet specific application needs. This ensures a tailored fit for various mechanical systems.

Titanium Rod Ends

Titanium rod ends are used in specialized applications that require high performance, lightweight construction, and exceptional durability.

Aerospace and Aviation

Titanium rod ends are frequently used in aerospace applications due to their superior strength-to-weight ratio. They are ideal for use in actuators, control linkages, and structural components in aircraft and spacecraft, where weight reduction is crucial without sacrificing strength.

High-Performance Motorsports

In motorsports, particularly in Formula 1 and other racing environments, titanium rod ends are favored for suspension systems, steering linkages, and chassis connections, where reduced weight and high strength contribute to faster speeds and improved vehicle handling.

Marine Applications

Titanium’s resistance to corrosion, especially in saltwater environments, makes it an ideal material for marine applications. Titanium rod ends are used in boat rigging, steering systems, and control linkages, where they are exposed to water and harsh marine conditions.

Medical Devices and Equipment

Due to titanium’s biocompatibility and resistance to corrosion, titanium rod ends are used in medical equipment, including prosthetics and orthopedic devices. The material’s strength and lightweight properties are crucial for providing reliable, long-lasting solutions.

Custom and High-Performance Manufacturing

Titanium rod ends are used in high-performance machinery, including custom-built industrial equipment, high-end robotics, and even racing drones, where minimizing weight without compromising strength is essential for optimal performance.

Superior Strength-to-Weight Ratio

One of the most notable advantages of titanium rod ends is their exceptional strength-to-weight ratio. Titanium is stronger than many steels but is significantly lighter, making it ideal for applications where both strength and weight savings are critical.

Corrosion Resistance

Titanium has outstanding resistance to corrosion, including in extreme environments such as saltwater, acids, and other harsh chemicals. This makes titanium rod ends particularly well-suited for marine, aerospace, and high-temperature applications.

Durability and Longevity

Titanium is highly durable, able to withstand high stresses, impacts, and temperature variations. It has a longer service life than many other metals and does not degrade or rust, making titanium rod ends an excellent choice for long-term performance.

Heat Resistance

Titanium has excellent heat resistance and can perform at high temperatures without compromising its structural integrity. This property makes it ideal for high-performance automotive and aerospace applications where heat exposure is common.

Low Maintenance

Titanium’s resistance to corrosion, wear, and fatigue means that titanium rod ends require minimal maintenance and do not need frequent replacements. Their longevity and performance reduce downtime and maintenance costs, making them a cost-effective solution in the long run.

Customization and Precision

Titanium can be precisely machined to tight tolerances, allowing for the production of custom rod ends that meet specific application requirements. Whether for a unique mechanical system or a performance-focused build, titanium rod ends offer tailored solutions.

Biocompatibility

Titanium’s biocompatibility makes it an excellent material for medical and prosthetic applications, where both strength and a non-reactive surface are essential.

Carbon Rod Ends

Carbon steel rod ends are used in a variety of demanding applications where strength, reliability, and cost-effectiveness are crucial.

Automotive and Motorsports

Carbon steel rod ends are commonly found in automotive suspension systems, steering linkages, and control arms. They are particularly useful in motorsports, where they are used for suspension linkages and steering systems in vehicles that require high performance and durability under stress.

Heavy Equipment and Machinery

Carbon steel rod ends are used in construction and agricultural machinery, such as in hydraulic systems, excavators, loaders, and other heavy-duty equipment. These rod ends handle high load-bearing requirements and are designed for tough working conditions.

Industrial Equipment

Carbon steel rod ends are also used in various industrial machinery applications, including conveyors, actuators, robotics, and pivot joints. They provide strong, durable, and cost-effective solutions for mechanical linkages in factories and production lines.

Aerospace and Defense

In aerospace applications, carbon steel rod ends are often used in actuators, control linkages, and other parts of aircraft that need to withstand high mechanical loads. They are especially suitable for applications where extreme weight reduction is not a priority but high strength is essential.

Agricultural Equipment

These rod ends are used in various agricultural machinery systems, including steering mechanisms and hydraulic linkages, offering the durability needed for extended operation in rough conditions.

High Strength

Carbon steel rod ends provide excellent strength and are capable of withstanding high mechanical stresses and loads. This makes them suitable for heavy-duty applications such as machinery, automotive suspension systems, and other systems where high strength is essential.

Durability and Longevity

Carbon steel is known for its durability and ability to withstand significant wear and tear. Carbon steel rod ends perform reliably over long periods, making them ideal for industries that require components to function in high-stress environments without frequent replacements.

Cost-Effective

Compared to materials like titanium and stainless steel, carbon steel rod ends offer a more affordable solution while still providing high strength and durability. This makes them a popular choice for applications where cost efficiency is important without sacrificing performance.

Customization and Precision

Carbon steel is easy to machine, allowing for precise manufacturing of custom rod ends to meet specific design requirements. This makes it a great option for applications needing custom sizes or configurations, such as in automotive and industrial machinery.

Fatigue Resistance

Carbon steel rod ends offer good resistance to fatigue and stress, making them suitable for applications involving repetitive movements or cyclic loading, such as in automotive suspensions and heavy machinery.

Corrosion Resistance

While not as corrosion-resistant as stainless steel or titanium, carbon steel rod ends can be coated with protective layers (such as zinc or chrome plating) to enhance their resistance to corrosion, making them suitable for moderate environmental exposure.

Versatility

Carbon steel rod ends are versatile and can be used in a wide range of industries, including automotive, industrial machinery, agriculture, and aerospace. Their robustness and performance under various conditions make them a trusted choice for numerous mechanical applications.

Heat Resistance

Carbon steel rod ends maintain good structural integrity at moderate temperatures, making them suitable for applications in environments where heat exposure is moderate, such as in automotive or industrial machinery.

CUSTOMACHINING

Precision Rod Ends On Vehicels

Why Choose Customachining?

Turn Concepts Into Reality

All information and uploads are secure and confidential.

CUSTOMACHINING

Latest Blogs

Request a Quote

If you already have the drawings, please send email to [email protected] directly for an instant quote.

Work with Customachining

Get a CNC Machining Solution with Easy

Let’s Start Our Cooperation with the 3 steps to start now!

1. Tell Us What You Need

Send us your request with details and share your idea.

2. Get Solution and Quote

We will work on the best solution base on your request and send you a specific quote within 24 hours.

3. Support at All Times

Whether it is before or after the sale, we are always here to support you.