Laser Cutting SErvice

What is Laser Cutting?

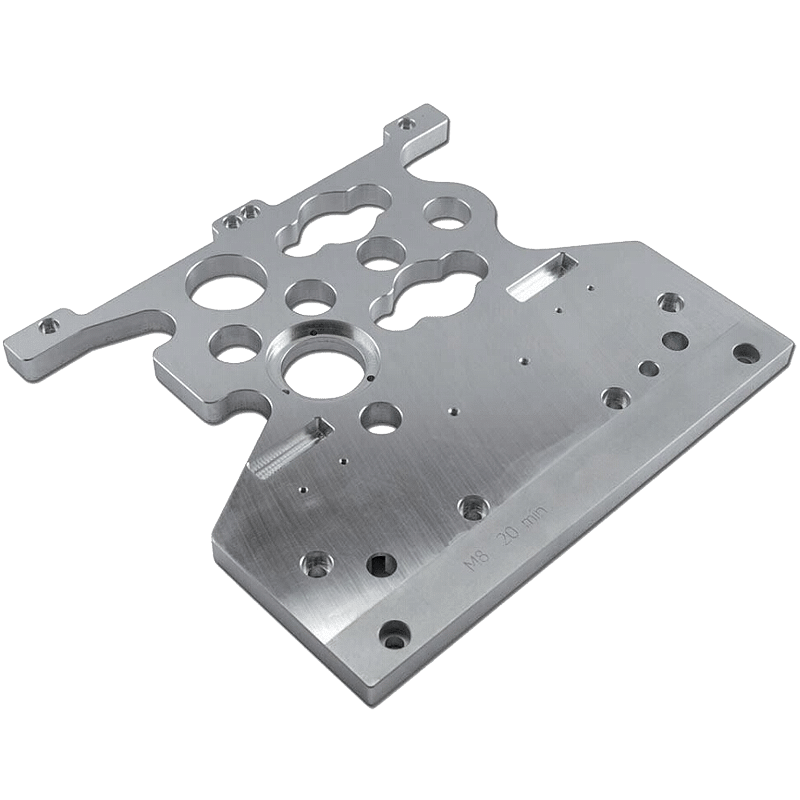

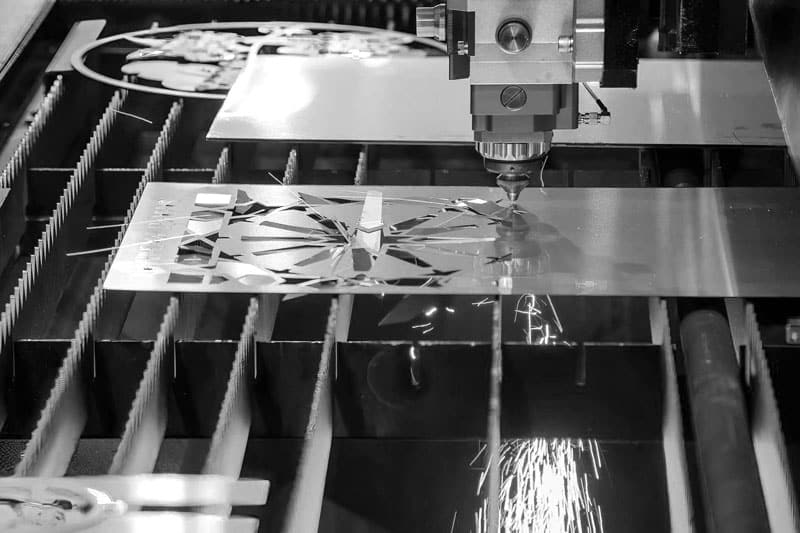

Laser cutting is a manufacturing process that uses a high-powered laser beam to cut, shape, or engrave materials with precision. The laser beam is directed onto the material, heating and melting it to achieve a precise cut. This technology is versatile and can be used on various materials, including metals, plastics, wood, and more. It is known for its high accuracy, efficiency, and ability to create intricate designs, making it widely used in industries such as automotive, aerospace, electronics, and manufacturing. Laser cutting offers advantages like minimal waste, fast production times, and the capability to handle complex geometries.

Types of Laser Cutting

1. CO2 Laser Cutting

Using carbon dioxide lasers, known for their high precision and smooth surfaces, they are commonly used in industries such as automotive, aerospace and advertising. They can effectively cut, engrave and drill a variety of materials, including metal, plastic, wood and glass.

2. Fiber Laser Cutting

Utilizes a solid-state laser with optical fibers. It is highly efficient and effective for cutting metals, including stainless steel, aluminum, and brass. Offers fast cutting speeds and is particularly useful for high-precision work and thin materials.

3. Nd Laser Cutting (Neodymium-doped Yttrium Aluminum Garnet)

A solid-state laser that can work in both continuous and pulsed modes. Suitable for cutting and engraving metals and some ceramics. It’s often used in the medical and electronics industries.

4. Nd(Neodymium-doped Yttrium Orthovanadate) Laser Cutting

Similar to Nd,but with better beam quality and more efficient at cutting thinner materials. Often used for precision marking and fine cutting tasks, including in the electronics industry.

5. Diode Laser Cutting

Uses diode lasers, typically lower power and used for applications requiring fine precision and intricate details. Commonly used in engraving and fine cutting of non-metallic materials.

Our Capability of High Precision Laser Cutting?

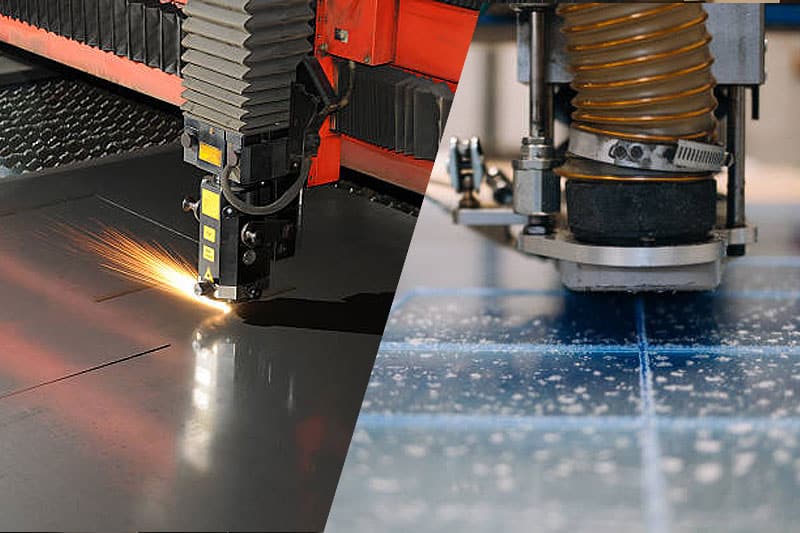

Advanced Laser Cutting Equipment

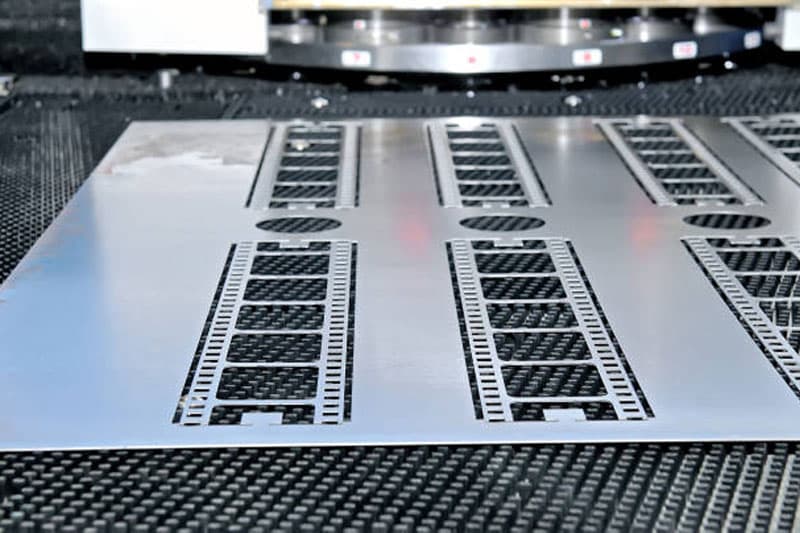

We have different equipment to meet the needs of laser cutting of different materials. Among the equipment for laser cutting of metal sheets, we use TruLaser 3040. The TruLaser 3040 is a high-performance laser cutting machine manufactured by TRUMPF, designed specifically for the metalworking industry. It features a 3200-watt CO2 laser capable of efficiently cutting various metal materials, including steel (up to 20 mm thick), stainless steel (up to 12 mm), and aluminum (up to 8 mm). The machine offers a spacious working area of 4000 x 2000 x 115 mm, making it ideal for large workpieces.

Equipped with an automatic pallet changer, a conveyor belt for small parts and scrap removal, and the Siemens Sinumerik 840 D control unit, the TruLaser 3040 ensures precision in operation. It also includes programmable features such as cutting gas pressure and laser power control, enhancing its flexibility and accuracy across different applications. Additionally, safety systems like light curtains and a multi-chamber exhaust system ensure safe and efficient operation .

Material Compatibility

Our laser cutting services specialize in working with a variety of materials, including metals and plastics. This broad material compatibility allows us to meet the diverse project needs of various industries. Whether you’re working with plastic or solid metal, our technology ensures precise, reliable cuts that are customized to the specific characteristics of each material.

Cutting Precision

We pride ourselves on delivering outstanding cutting precision with our advanced laser technology. Capable of achieving tight tolerances and intricate details, our equipment ensures that every cut meets exact specifications. This high level of accuracy is essential for projects requiring meticulous designs and flawless execution, making our services ideal for high-quality, detailed work..

Handle Complex Design

Our laser cutting capabilities offer remarkable flexibility, accommodating complex shapes and detailed patterns with ease. We are equipped to handle custom designs and unique geometries, enabling us to turn intricate concepts into reality. This adaptability ensures that even the most demanding design requirements are met with precision and creativity.

Post-Processing Capabilities

In addition to cutting, we provide comprehensive post-processing services such as surface finishing, assembly, and more. These additional capabilities enhance the quality and functionality of the final product. By offering a complete range of post-processing options, we ensure that every aspect of your project is addressed, resulting in a polished and fully realized end product.

Production Efficiency

Efficiency is a cornerstone of our laser cutting services. Our advanced equipment allows for rapid cutting speeds and high production volumes, optimizing workflow and reducing turnaround times. We are committed to delivering prompt and reliable service, ensuring that large-scale projects and tight deadlines are managed effectively without sacrificing quality.

Turn Concepts Into Reality

All information and uploads are secure and confidential.

CUSTOMACHINING

CNC Machining Surface Finishing

Request a Quote

If you already have the drawings, please send email to [email protected] directly for an instant quote.

Work with Customachining

Get a CNC Machining Solution with Easy

Let’s Start Our Cooperation with the 3 steps to start now!

1. Tell Us What You Need

Send us your request with details and share your idea.

2. Get Solution and Quote

We will work on the best solution base on your request and send you a specific quote within 24 hours.

3. Support at All Times

Whether it is before or after the sale, we are always here to support you.