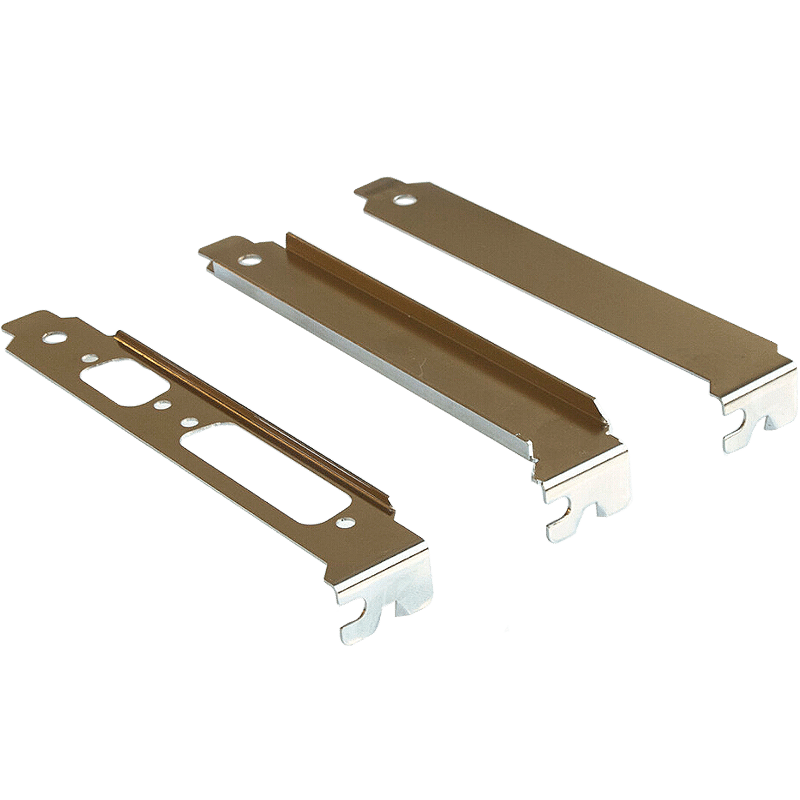

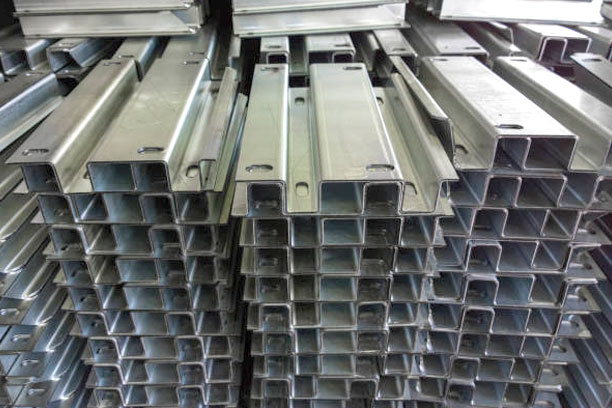

Sheet Metal Bending

What is Sheet Metal Bending?

Sheet metal bending is the process of deforming a metal sheet into a desired shape by applying force to create a bend at a specific angle. The bending process is commonly used in the production of components in various industries such as automotive, aerospace, electronics and construction.

The bending process usually involves placing a metal sheet/board between a punch and die. The punch presses the metal into the die, creating the bend. The angle and radius of the bend can be controlled by adjusting the position of the punch and die and the amount of force applied. Key factors in sheet metal bending include material type and thickness, bend radius, grain orientation, tool selection, and springback compensation.

CUSTOMACHINING

Sheet Metal Bending Capabilities

| Max. Part Size | 12 x 3 m |

| Metal Bending Forces | Max. 1000 tons |

| Bending Line Length | Max. 7200 mm |

| Bending Thickness | Max. 60 mm |

| General Tolerances | +/- 0.020 mm |

| Bend to edge/hole, single surface | +/- 0.254 mm |

| Bend Radius | refer to material thickness |

| Bend Angle | +/- 1° |

| Bend Cutting Area | 12 x 3 m |

| Lead Time | 5 Days |

Turn Concepts Into Reality

All information and uploads are secure and confidential.

Seven Key Factors

For

High-Quality Sheet Metal Bending

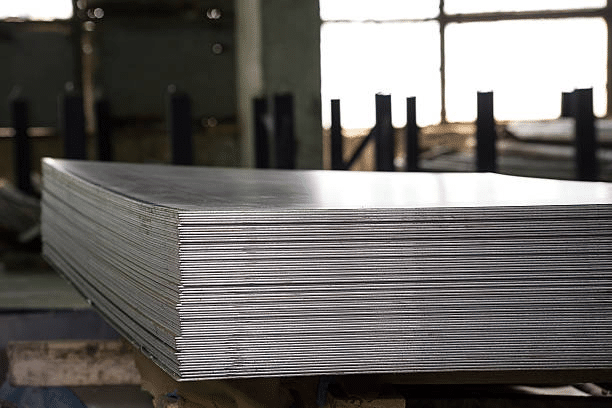

Material Thickness and Type

The thickness and type of the metal greatly influence the bending process. Different metals have different ductility and spring-back properties, which must be accounted for to achieve the desired bend.

Bend Radius

The inside bend radius should be consistent with the material’s thickness to prevent cracking or deformation. Selecting the correct bend radius is essential for maintaining material integrity.

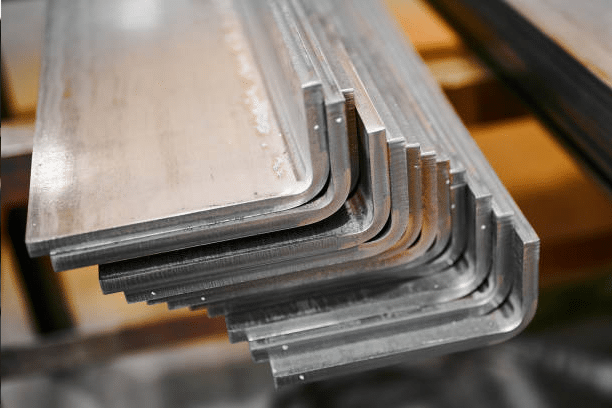

Bend Direction and Grain Orientation

The direction of the bend relative to the metal’s grain structure affects the outcome. Bending against the grain increases the likelihood of cracks, so it’s generally better to bend with the grain.

Tooling Selection

The choice of tools, including the punch and die, must match the specific requirements of the project, considering factors like bend angle, material thickness, and the complexity of the bend.

Tolerance and Precision

Tight tolerances are crucial for ensuring parts fit together correctly in assembly. The bending process must be precise to maintain the required dimensions.

Spring-back Compensation

Metals tend to spring back slightly after bending. Adjustments need to be made to account for this spring-back to ensure the bend angle remains accurate.ure safe and efficient operation .

Consistency and Repeatability

Especially in high-volume production, the ability to consistently produce identical bends is vital. This requires well-maintained machinery and careful monitoring of the bending process.

CUSTOMACHINING

CNC Machining Surface Finishing

Request a Quote

If you already have the drawings, please send email to [email protected] directly for an instant quote.

Work with Customachining

Get a CNC Machining Solution with Easy

Let’s Start Our Cooperation with the 3 steps to start now!

1. Tell Us What You Need

Send us your request with details and share your idea.

2. Get Solution and Quote

We will work on the best solution base on your request and send you a specific quote within 24 hours.

3. Support at All Times

Whether it is before or after the sale, we are always here to support you.