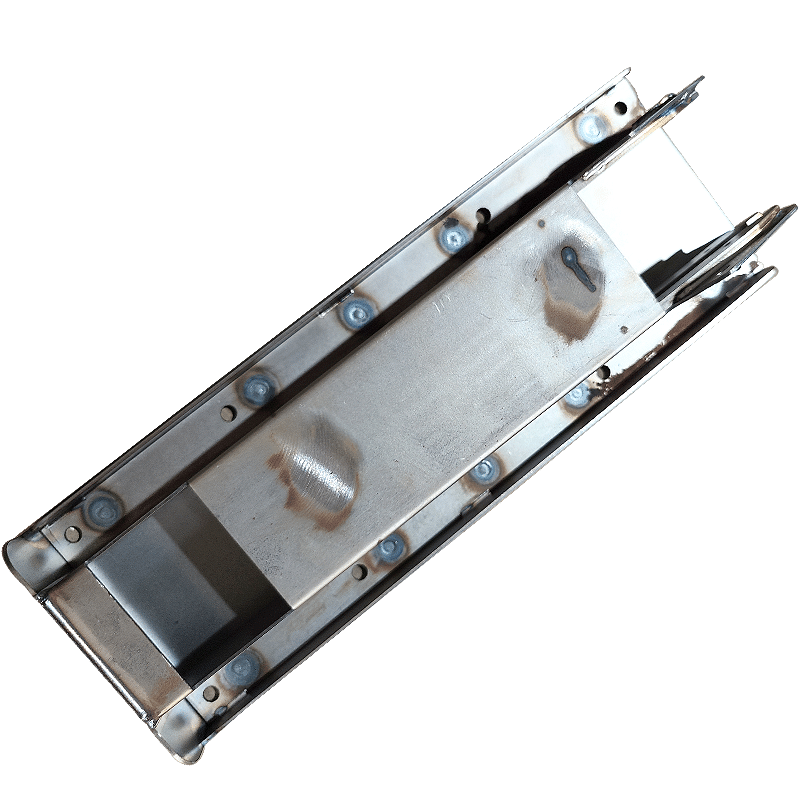

Sheet Metal Welding

Customachining Welding Advantages

Sheet Metal Welding Process Capabilities

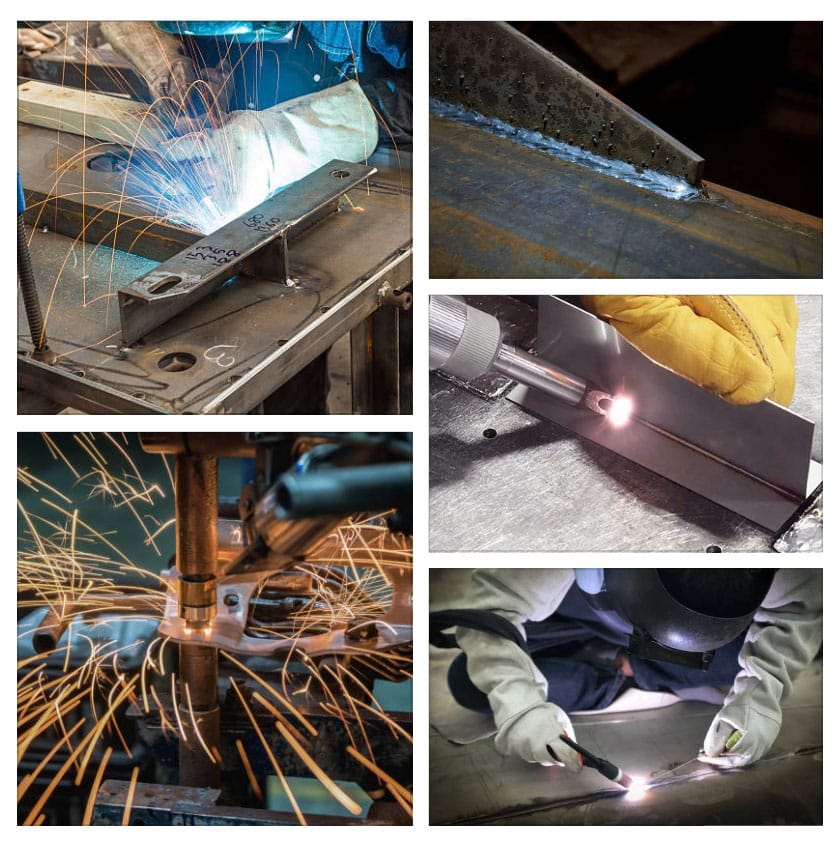

1. MIG Welding (Metal Inert Gas)

MIG welding uses a continuous wire feed as an electrode and an inert gas like argon or a gas mix as a shielding gas to protect the weld pool from contamination.

2. TIG Welding (Tungsten Inert Gas)

TIG welding employs a non-consumable tungsten electrode to produce the weld. An inert gas, usually argon, protects the weld area from contamination.

3. Spot Welding

Spot welding involves applying pressure and an electrical current to the metal sheets, generating heat at the contact point to form a weld. It is commonly used in the automotive industry.

4. Seam Welding

Seam welding is similar to spot welding but instead uses wheel-shaped electrodes to create a continuous weld seam along the joint. It is often used in the production of leak-proof containers.

5. Laser Welding

Laser welding utilizes a concentrated beam of light to melt and fuse materials together. It is precise and can be automated for complex shapes.

Turn Concepts Into Reality

All information and uploads are secure and confidential.

Welding Type Comparison and Application

1. MIG vs. TIG

MIG is faster and easier to learn, making it ideal for thicker metals and large-scale projects, while TIG provides greater precision for thinner materials and intricate work.

2. Spot Welding vs. Seam Welding

Spot welding is best for quick, localized welds on thin sheets, whereas seam welding is essential for creating continuous, leak-proof welds.

3. Laser Welding

Stands out for its precision and speed, particularly in applications requiring minimal distortion and high control, such as in aerospace or medical devices.

Quality Control in Sheet Metal Welding

Quality control in sheet metal welding is crucial to ensuring the structural integrity and safety of welded components. Various inspection methods, such as visual inspection, X-ray, and ultrasonic testing, are employed to detect defects like cracks, porosity, or incomplete fusion in the welds. Visual inspection is often the first step, providing a quick assessment of the weld surface for any visible flaws. For more detailed analysis, X-ray inspection reveals internal defects by capturing images of the weld’s internal structure, while ultrasonic testing uses high-frequency sound waves to detect inconsistencies within the weld without damaging the material. Adhering to industry standards and certifications is essential, as it ensures that the welding process meets the required specifications for quality and safety, thereby preventing failures in critical applications. These standards guide the quality control procedures, ensuring that each weld is consistently produced to the highest standard, which is particularly important in industries such as aerospace, automotive, and construction, where the integrity of welded joints is paramount.

Common Metals for Sheet Metal Welding

In sheet metal welding, the choice of material plays a critical role in determining the weld quality, strength, and overall performance of the final product. Commonly used metals include aluminum, stainless steel, and carbon steel, each offering unique welding characteristics. Aluminum is lightweight and corrosion-resistant but requires careful control of heat input during welding due to its high thermal conductivity and tendency to warp. Stainless steel is known for its corrosion resistance and strength, making it ideal for various applications; however, it requires attention to prevent issues like warping and oxidation during welding. Carbon steel, a widely used material, is easier to weld compared to aluminum and stainless steel, thanks to its lower thermal conductivity and higher melting point, but it must be properly treated to prevent rust and maintain structural integrity. Each metal’s characteristics demand specific welding techniques and considerations to achieve optimal results in sheet metal fabrication.

Request a Quote

If you already have the drawings, please send email to [email protected] directly for an instant quote.

Work with Customachining

Get a CNC Machining Solution with Easy

Let’s Start Our Cooperation with the 3 steps to start now!

1. Tell Us What You Need

Send us your request with details and share your idea.

2. Get Solution and Quote

We will work on the best solution base on your request and send you a specific quote within 24 hours.

3. Support at All Times

Whether it is before or after the sale, we are always here to support you.