The Evolution of CNC Machining: From Manual Milling to Advanced Automation

The Evolution of CNC Machining has revolutionized manufacturing. The journey from manual milling to advanced automation reflects significant technological advancements and changes in manufacturing practices.

The Early Days: Manual Milling

In the early 20th century, milling machines were manually operated. Skilled machinists would use handwheels and dials to position cutting tools precisely, based on blueprints and physical measurements. This process was labor-intensive and required a high level of expertise. Each part produced was a testament to the machinist’s skill, but consistency and precision were challenging to maintain across large production runs.

The Advent of Numerical Control

The development of numerical control (NC) in the 1940s and 1950s marked the first major leap in machining technology. NC machines used punched tape and later magnetic storage to control machine movements. This innovation allowed for greater precision and repeatability, reducing the dependency on manual labor and human error.

The Rise of CNC

The 1970s saw the introduction of Computer Numerical Control (CNC) machines, which integrated computer technology with machining. CNC machines used computer programming to control all aspects of the machining process. This allowed for more complex and precise operations, higher speeds, and greater flexibility. Operators could now program machines to produce parts with intricate geometries and tight tolerances.

Advancements in CNC Technology

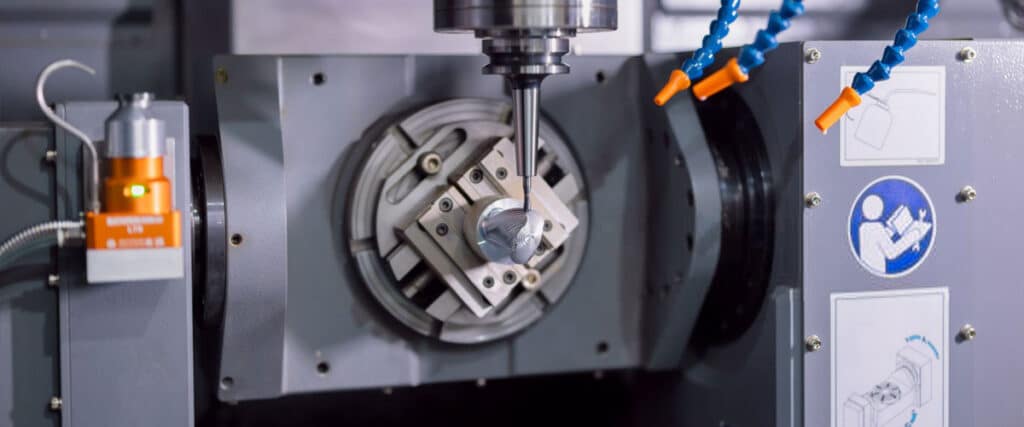

Over the past few decades, CNC technology has continued to evolve. Modern CNC machines are equipped with advanced features such as multi-axis machining, automated tool changers, and real-time monitoring systems. These advancements have significantly increased productivity, reduced waste, and improved the quality of finished products.

The Future of CNC Machining

The future of CNC machining is poised to see further innovations with the integration of artificial intelligence (AI), machine learning, and the Internet of Things (IoT). These technologies will enable smarter, more adaptive manufacturing processes. AI can optimize machining parameters in real-time, while IoT can provide valuable data for predictive maintenance and process improvements.

In summary, the evolution of CNC machining from manual milling to advanced automation has transformed manufacturing, making it more efficient, precise, and adaptable. As technology continues to advance, CNC machining will remain at the forefront of modern manufacturing, driving innovation and efficiency.