Wire edm services

What is Wire EDM?

Wire EDM uses a thin brass or molybdenum wire as an electrode to remove material by generating sparks between the workpiece and the electrode. A certain discharge gap must be maintained between the workpiece and the electrode, and must be cooled and flushed by insulating liquid to It takes away the waste chips generated by cutting and prevents the electrode from overheating.

The process advantages of Wire EDM are

1. High precision

2. Ability to process complex shapes

3. Suitable for processing materials with higher hardness

4. The workpiece will not generate mechanical stress during processing or deformation

5. The finish is good and no further surface treatment is usually required

Types Of EDM Machining

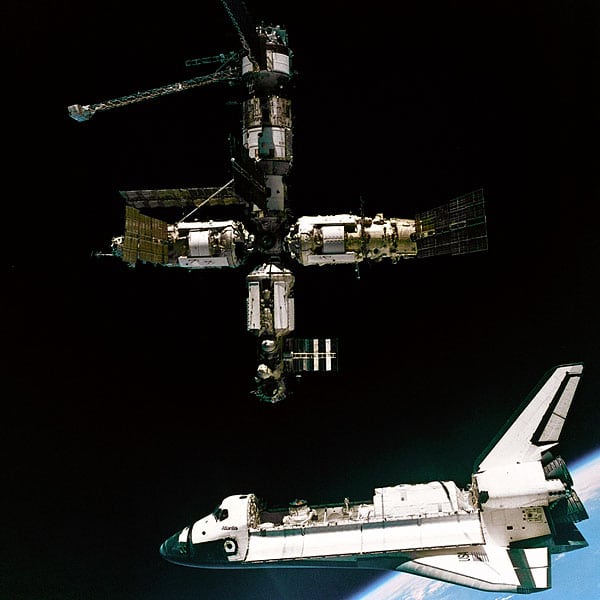

1. Wire electrical discharge cutting (Wire EDM) uses thin metal wires as electrodes to cut complex shapes and small details through electric discharge. It is suitable for mold manufacturing, precision parts, medical equipment and aerospace components.

2. Sinker EDM uses pre-designed electrodes for forming processing and is suitable for manufacturing complex molds, grooves, blind holes and special-shaped parts.

3. Hole Drilling EDM uses slender electrodes for drilling. It is suitable for processing small diameter deep holes and micro holes. It is often used in nozzles, fuel injectors and medical equipment.

4. Fast Hole EDM Drilling is designed for rapid drilling and is suitable for high-strength alloys. It is widely used in the manufacture of cooling holes, turbine blades and gas turbine components.

5. Electrolytic EDM (EDM Combined with Electrochemical Machining, ECDM) combines the advantages of EDM and electrochemical machining, improves material removal efficiency and processing surface quality, and is suitable for precision parts of high-strength, difficult-to-machine materials.

Through these different types of EDM processing technologies, various needs for complex shape, high-precision and high-hardness material processing in various industrial fields can be met.

CUSTOMACHINING

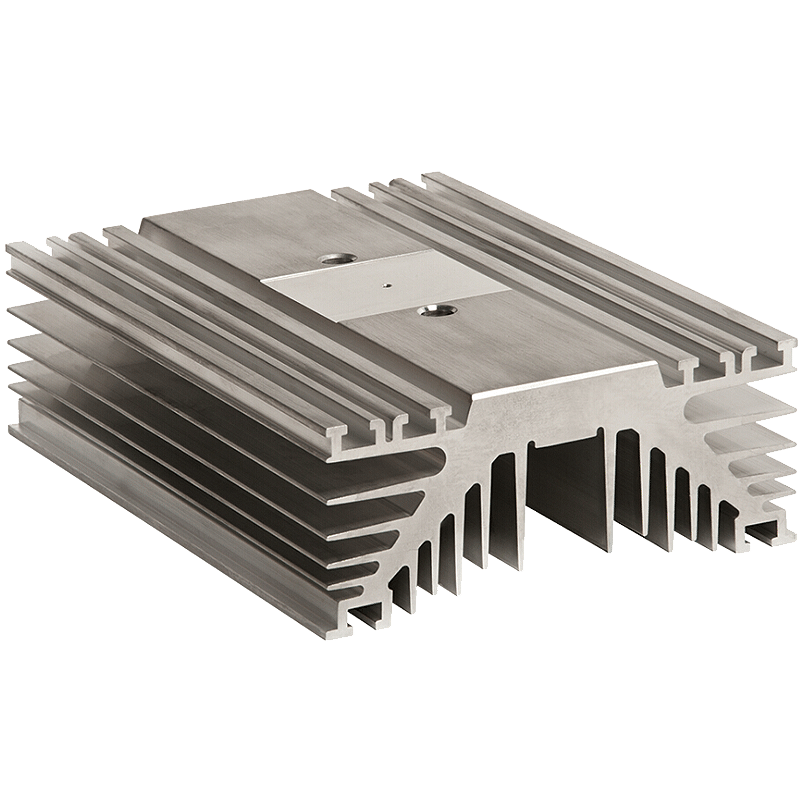

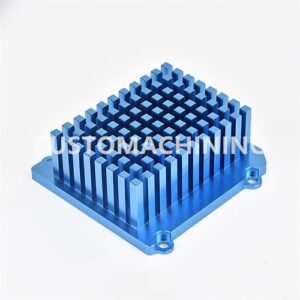

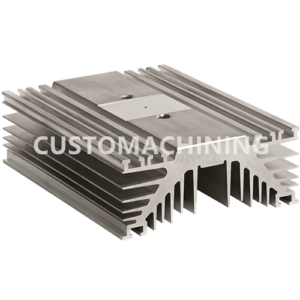

Wire EDM Parts Showroom

CUSTOMACHINING

Why Choose Our Wire EDM Services

Quick Quote

Get instant quotes with our streamlined online form. Just provide your project details, and receive a fast, accurate estimate tailored to your specific requirements, helping you plan and budget effectively.

High Efficiency

Utilizing cutting-edge equipment and optimized processes, we ensure high-efficiency production. This means faster turnaround times without compromising quality, allowing you to meet tight deadlines and keep your projects on track.

High Precision

Our EDM machining delivers exceptional precision with tolerances ranging from +/-0.001″ to 0.005″. Our expertise in custom components ensures unmatched accuracy, making us your go-to partner for high-precision manufacturing needs.

24/7 Support

We offer round-the-clock support to guarantee your satisfaction. Our expert engineers are available 24/7 to assist with any queries or modifications, ensuring smooth and continuous progress for your projects.

CUSTOMACHINING

Materials For Wire EDM

Check The Characteristics of Materials to Choose the Best One for Your Project, Click “View All” to Learn More.

| Aluminum | 2024, 5052, 5083, 6063, 6061, 6082, 7050, 7075 |

| Stainless Steel | 17-4, 18-8, 303, 304, 316, 416, 420, 430, 410, 440C, 321, 347 |

| Brass | C36000, C26000, C28000, C37700, C48500, C22000, C23000, C24000 |

| Copper | C11000, C10100, C14500, C17200, C18200, C19400, C10200, C12200 |

| Titanium | Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, Grade 7, Grade 9 |

| Steel | A36, 1018, 1020, 1045, 4140, 4340, 8620, 9310 |

| Plastic | POM, ABS, Nylon, PEEK, PTFE, PAI, PMMA, PEI, HDPE, PVC, PPS, PC, UHMW |

CUSTOMACHINING

CNC Surface Finishes For CNC Turning Services

Check The Characteristics of Materials to Choose the Best One for Your Project, Click “View All” to Learn More.

| As Machined | Surface left as is post-machining, shows tool marks. (Ra 3.2μm / Ra 126μin) |

| Smoothing | Reduces surface roughness, improves appearance and texture. (Ra 1.6μm / Ra 63μin) |

| Painting | Applies a colored coating for aesthetics and protection. |

| Passivation | Enhances corrosion resistance by removing free iron from surfaces. |

| Powder Coating | Durable, powder-applied finish, baked to form a hard coat. |

| Anodizing II | Electrochemical process creating a shiny or dull, corrosion-resistant layer. |

| Anodizing III Hard Coat | Thick, wear-resistant anodized layer for high durability. |

| Polishing | Creates a smooth, shiny surface by mechanical abrasion or chemical treatment. (Ra 0.8μm / Ra 32μin or better) |

| Black Oxide | Black conversion coating providing corrosion resistance. |

| Bead Blasting | Bead blasted with glass beads to clean and texture surfaces. |

| Sandblasting | Uses high-pressure sand to clean and texture surfaces, creating a matte finish. |

| Chrome Conversion Coating | Improve the corrosion resistance while maintaining conductive properties. |

| Plating | Corrosion resistance, with solderability and electrical conductivity, various material options, such as zinc, chrome, nickel, tin, etc.. |

CUSTOMACHINING

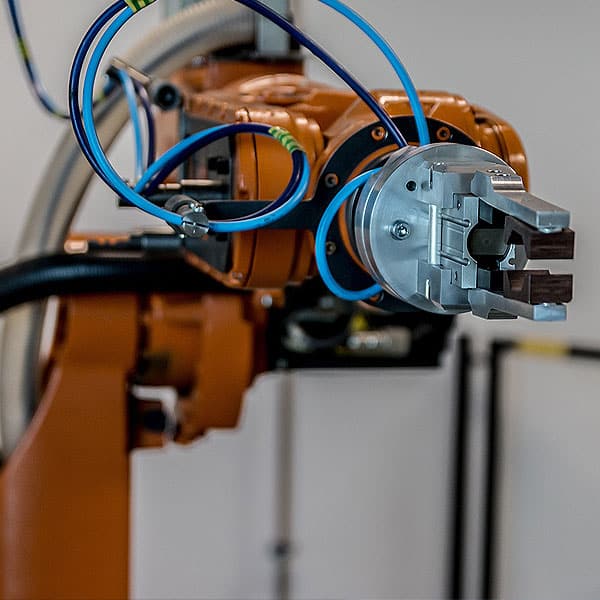

Highlighted Industries We Served

We Serve Aerospace, Automotive, Automation, Medical, Robotics,Energy, Consumer Products, Industrial, ect.

Request a Quote

If you already have the drawings, please send email to [email protected] directly for an instant quote.

Work with Customachining

Get a CNC Machining Solution with Easy

Let’s Start Our Cooperation with the 3 steps to start now!

1. Tell Us What You Need

Send us your request with details and share your idea.

2. Get Solution and Quote

We will work on the best solution base on your request and send you a specific quote within 24 hours.

3. Support at All Times

Whether it is before or after the sale, we are always here to support you.